The history of supply chain management is filled with examples of promising projects that failed to meet their goals. These failures often share a common thread: a lack of proper attention to the concepts of time during the project’s design and implementation phases. Whether it’s a mismatch between the company’s growth trajectory and system capacity, unrealistic ROI expectations, or poorly anticipated peak demands, neglecting the time factor can doom even the best-intentioned projects.

Fortunately, there are strategies to navigate these pitfalls and set your supply chain projects up for success. Here’s how to ensure your initiatives are prepared to stand the test of time.

Why Projects Fail: The Time Trap

Supply chain projects often falter due to a failure to adequately address these key time-related considerations:

- Planning Horizon & Growth Expectations – Many projects underestimate the company’s growth trajectory or fail to build flexibility into the design. When systems can’t scale alongside business needs, they quickly become obsolete.

- Payback Period Hurdles – To gain approval, projects are frequently designed around a limited ROI period. This short-term focus can constrain innovation and prevent future scalability.

- Critical Performance Timeframes – Peak seasons or promotional periods require supply chain systems to operate at maximum efficiency. Designs that aren’t tailored to handle these periods can crumble under pressure.

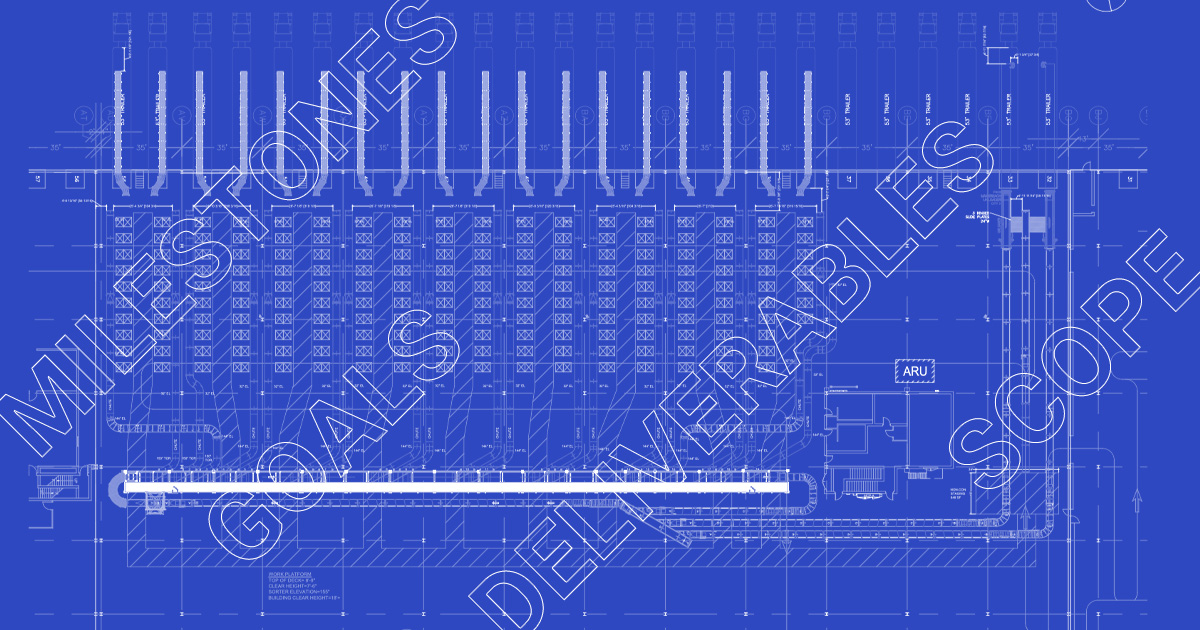

Four Ways to Beat the Time Trap

To address these challenges and ensure long-term success, supply chain leaders can take the following steps:

- Document & Align on Growth Expectations – Collaborate with stakeholders to clearly define the company’s expected growth trajectory. Whether it’s a 5%, 20%, or 50% increase in volume over the next five years, the system design must reflect these projections. This alignment minimizes surprises and ensures the solution fits both current and future needs.

- Plan for Fluctuations in Volume – Understanding when and how volume fluctuations will occur is crucial. Build a system with flexibility to handle demand peaks effectively. This requires addressing two critical aspects:

- Clearly define the percentage of upside demand events (like holiday spikes) that the system will be designed to manage.

- Develop a phased plan for expanding capacity when needed. For example:

- Extending operational hours during peak periods.

- Implementing temporary, scalable solutions such as putwalls or additional manual labor.

- Design with ROI & Payback Periods in Mind – Short payback periods often limit system capabilities. Address this by identifying how ROI requirements impact the design and document when additional investments will be necessary to meet future needs. For example, consider phasing in automation upgrades after achieving the initial ROI hurdle.

- Build Expansion Opportunities into the System – Incorporate flexibility for future growth:

- Allocate space for additional storage or processing areas.

- Select modular equipment or technology that can scale with minimal disruption.

- Include infrastructure (e.g., power and data) to support future upgrades.

Time-Savvy Supply Chain Projects Deliver Results

By addressing the complexities of time—planning horizons, critical periods, and ROI expectations—you can design supply chain solutions that grow with your business. Documenting growth expectations, planning for volume fluctuations, and designing for phased expansion ensures your systems won’t just meet today’s demands but will continue to deliver value for years to come.

Don’t let the time trap derail your next supply chain project. By incorporating these strategies, you’ll ensure your initiative stands as a testament to success, not a cautionary tale in the annals of supply chain history.

Ready to Build a Future-Proof Supply Chain?

At Lift Automation, we specialize in designing and implementing scalable material handling solutions that grow your business—and grow with your business. Whether you’re planning a new facility, upgrading existing operations, or preparing for peak demand, our team can help you avoid the time traps that lead to costly mistakes.

Contact us today to discuss how we can tailor a solution that meets your immediate needs while preparing you for the future. Let’s ensure your supply chain is ready for what’s next!