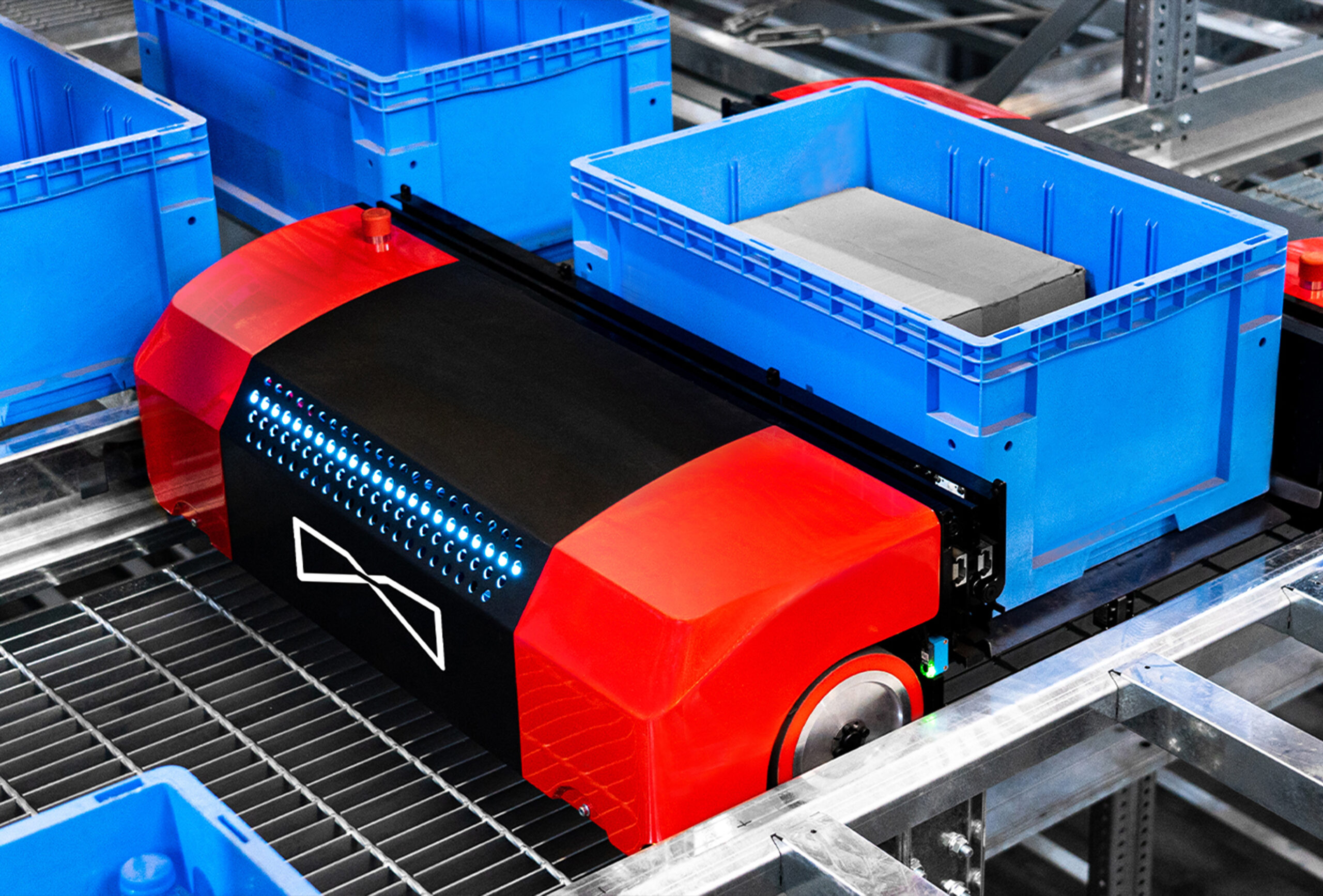

When a new Material Handling Equipment (MHE) system is installed, the journey to optimized, ROI-driven operations begins. But as many who have implemented these systems know, the road to that ideal state often involves setbacks, trial and error, and a fair share of frustrating days. This post explores the typical journey of MHE system adoption and highlights practical ways to accelerate this learning curve for faster, more effective ROI.

Many practitioners and researchers in operations management, industrial engineering, and organizational learning have observed similar patterns in adoption and optimization of new systems. For example:

- Change management literature often discusses the challenges of initial implementation and the importance of sustained effort for long-term success.

- Six Sigma and other quality management approaches recognize the value of data-driven experimentation and continuous improvement, which aligns with your later-stage observations.

- Human factors research in complex systems operation has noted similar patterns of initial caution followed by more sophisticated optimization as operators gain experience.

The MHE Adoption Journey

The typical MHE journey involves four steps. Knowing the steps ahead of time and planning together with your provider prepares you to achieve your goals more quickly.

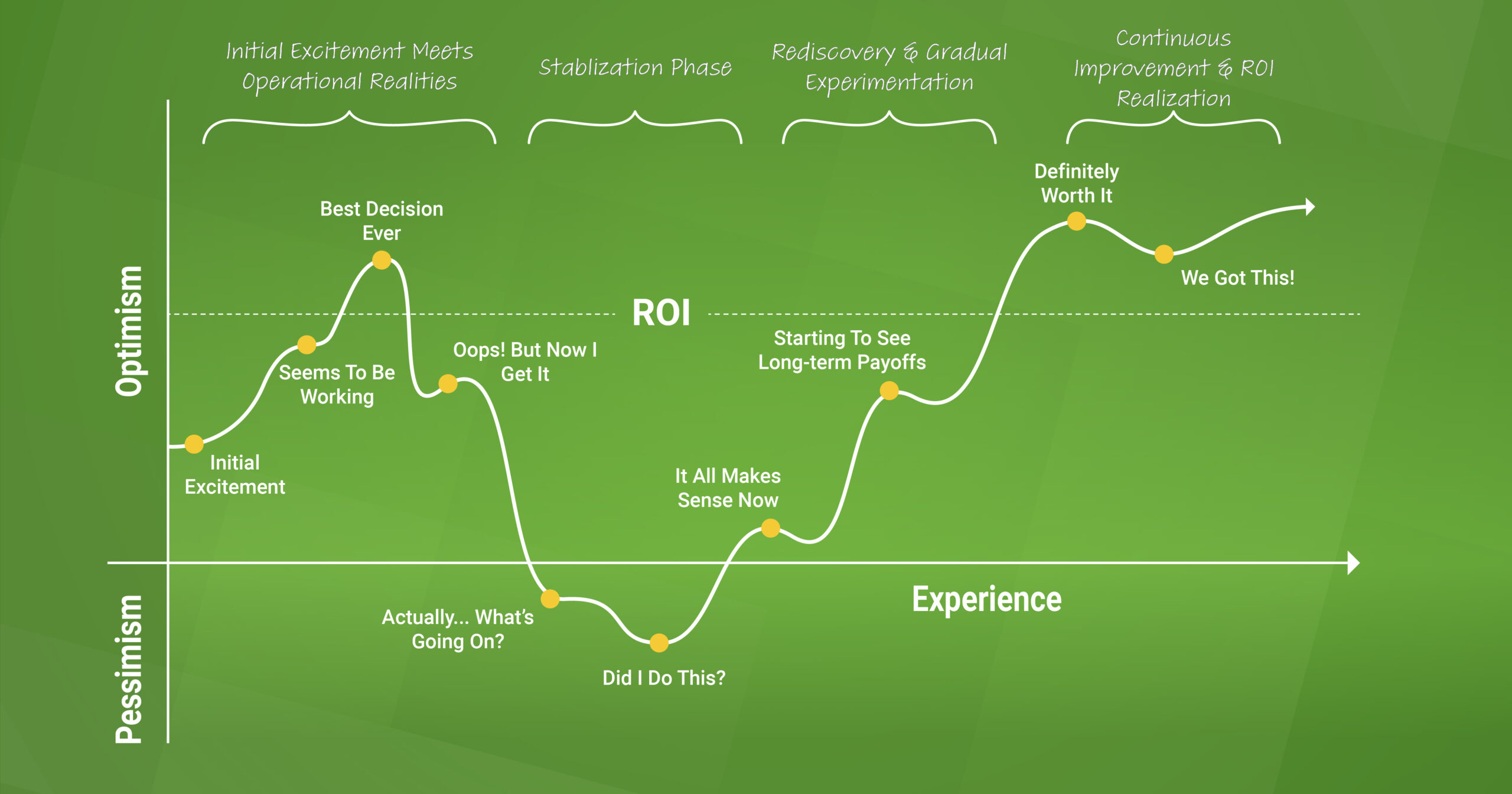

1. Initial Excitement Meets Operational Realities

When a new MHE system is introduced, there’s an initial wave of optimism. Operators are eager to explore and push the boundaries of the system’s capabilities. However, this phase often leads to what can be described as ‘the very bad day’—when misaligned settings cause operational disruptions and frustration begins to set in.

This stage is critical; it’s where the real learning begins as operators get their first taste of the system’s intricacies, understanding both its potential and its limitations.

2. The Stabilization Phase

Following early setbacks, operators frequently settle into a “baseline” approach, maintaining settings that are known to work, even if they aren’t maximizing productivity. This phase, though comfortable, often feels like a plateau. Operators become accustomed to steady performance and may hesitate to experiment further out of fear of disrupting the system.

This period can stretch over months or even years, and while it provides stability, the system’s true value remains partially locked. Many operators experience a sense of stalled potential here—an awareness that the system could do more but reluctance to risk change.

3. Rediscovery & Gradual Experimentation

After months (or even years), operators often become more comfortable and confident, leading them to gradually adjust settings in response to changing needs. This phase often brings a sense of renewed possibility. Adjustments are more controlled and thoughtful, fueled by a deeper understanding of the system’s nuances. Experimentation here typically involves:

- Incremental Improvements: Minor changes lead to measurable gains in efficiency.

- Data-Driven Decisions: Operators leverage analytics to inform decisions, aligning adjustments with operational goals.

Operators in this phase begin to realize that the system has more potential than they initially understood, sparking a new wave of enthusiasm and curiosity.

4. Continuous Improvement & ROI Realization

As operators grow more attuned to the system, something shifts. With insights gained from months of experience, they start experimenting again—this time with greater control and focus. The system transforms from a set of operational tools into a dynamic asset, adaptable to evolving business demands.

In this phase, each tweak and adjustment not only enhances efficiency but also initiates a cycle of continuous improvement. Here, operators unlock the full potential of their MHE system, not just achieving ROI but driving long-term value through ongoing refinements.

How to Achieve Your Goals

While the typical journey can take time, there are ways to fast-track this process. At Lift Automation, we support clients in climbing the learning curve faster by implementing proactive strategies that shorten the time to ROI. Here are some best practices:

Foster a Culture of Experimentation

Building a culture that values experimentation helps accelerate growth:

- Communicate Optimization Goals: Clearly convey the importance of ongoing optimization to all operators.

- Recognize and Reward: Celebrate innovative ideas and responsible risk-taking.

- Allocate Resources: Provide time and resources for safe experimentation.

Start with Controlled Experiments to Build Confidence

To build operator confidence and minimize risks:

- Start Small: Begin with small-scale adjustments on less critical parameters.

- Phase Experiments: Gradually expand the scope of experimentation.

- Implement Safeguards: Establish quick rollback procedures to handle setbacks.

Provide Ongoing Training & Education

Continued learning builds confidence, enabling operators to make smarter adjustments:

- Regular Training: Offer training on system functionality and optimization techniques.

- Case Studies: Share examples of successful adjustments from other facilities.

- Stay Updated: Encourage operators to stay current on industry best practices and innovations.

Ready to Unlock Your System’s Full Potential?

Every MHE journey has its highs and lows, but with the right approach, you can accelerate ROI and make the most of your investment. Contact Lift Automation today to learn how we can help your team unlock the full potential of your MHE system and fast-track your journey to success!