Eliyahu M. Goldratt’s The Goal introduced the Theory of Constraints (TOC)—a revolutionary approach to improving operational efficiency by identifying and addressing system bottlenecks. For distribution centers (DCs), Goldratt’s philosophy provides a powerful framework for optimizing processes and throughput, particularly when preparing for peak season demands.

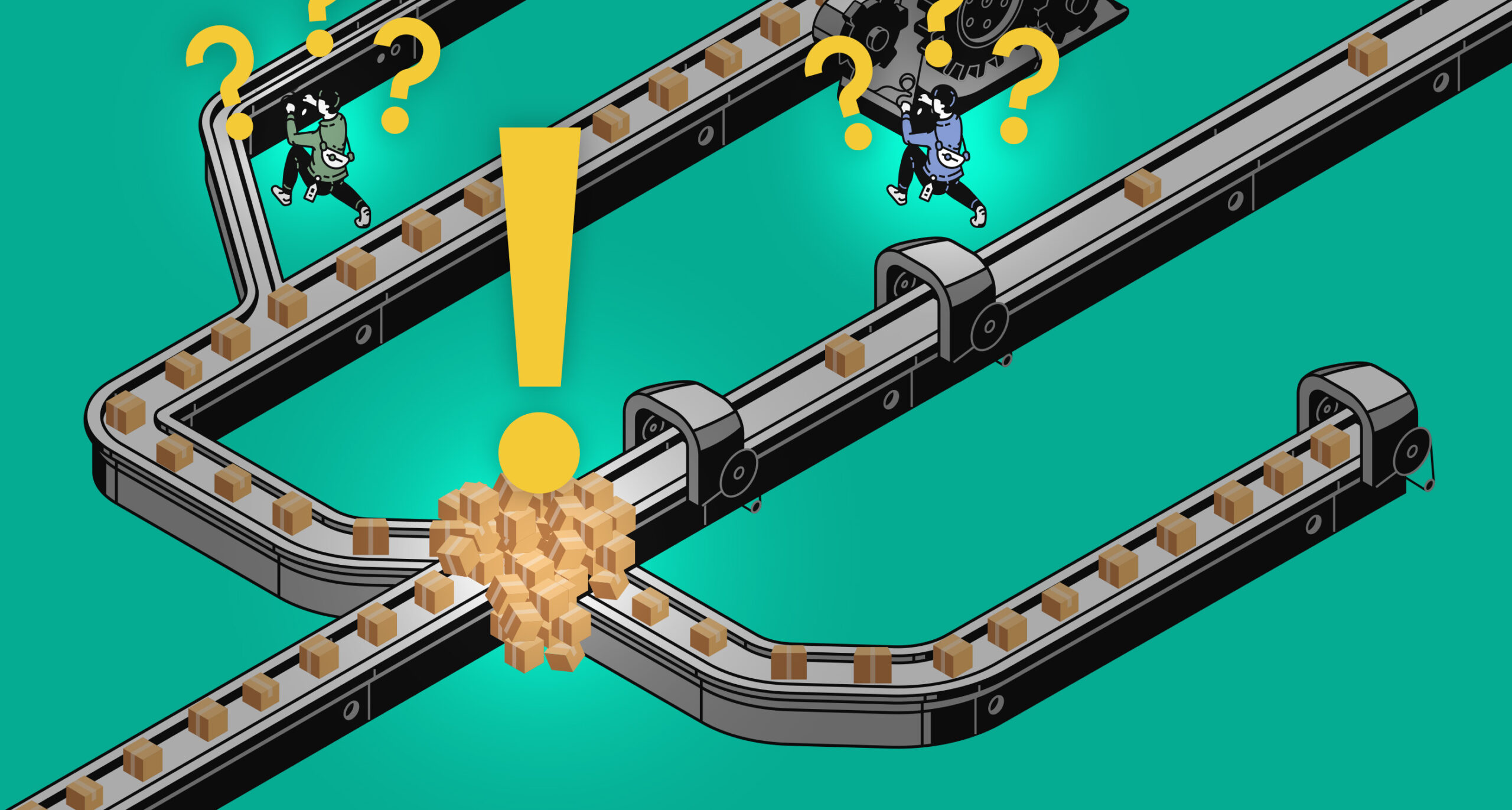

In The Goal, Goldratt emphasizes the importance of pinpointing the system’s constraint—the limiting factor that hinders overall performance. In a DC, this could be anything from bottlenecks in picking and sorting to delays in material handling. Instead of trying to improve every aspect of the operation, TOC directs attention to maximizing the performance of this key constraint, as it holds the greatest potential for boosting overall efficiency.

TOC also encourages continuous improvement, with all activities aligned toward achieving the DC’s primary goal—enhancing throughput, reducing lead times, and meeting demand as efficiently as possible. Applying these principles to DC design enables operators to identify and alleviate bottlenecks, streamline operations, and create a more agile, responsive supply chain. The result? A DC that’s not only more efficient but also more profitable and competitive.

Preparing Your Distribution Center for Peak Season

As a DC operator, peak season presents a set of unique challenges. Whether it’s Black Friday, holiday shopping, or other high-demand periods, your facility needs to operate at peak efficiency to manage the increased volume of orders. To thrive during these times, it’s crucial to design your distribution center to handle the stress while maintaining smooth operations.

Identifying Your Bottleneck

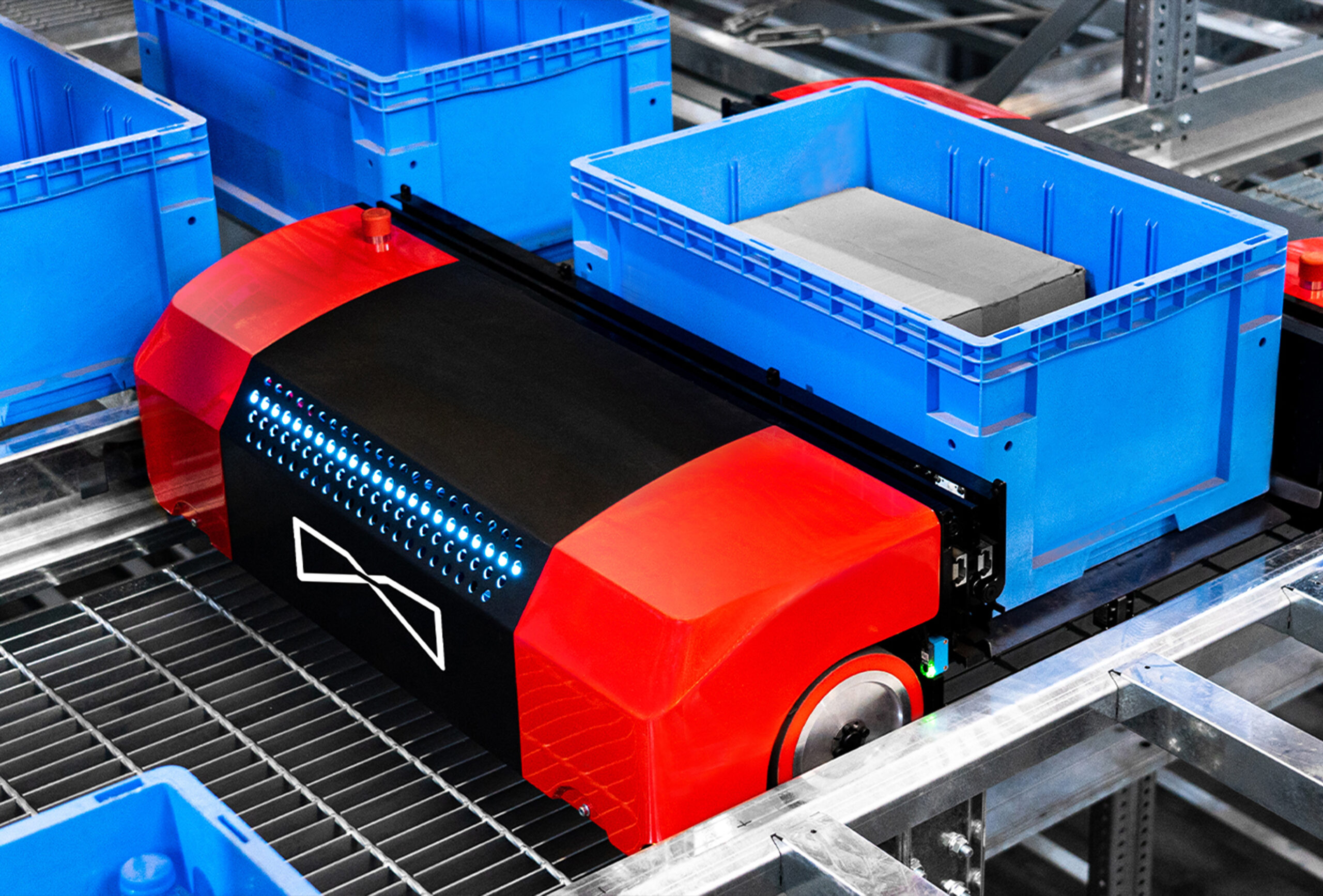

In distribution center design, especially for peak season, the bottleneck often involves the processes that require the most resources—typically unit picking and sorting at the order level. These functions are resource-intensive because they involve locating individual SKUs and bringing them together for order fulfillment. If these processes aren’t optimized, the entire operation can suffer from delays and inefficiencies.

Optimizing Your DC for Peak Season Success

To build a high-performing DC that can handle the demands of peak season, start by designing around your bottleneck. For most facilities, this means focusing on optimizing the picking process. A well-designed picking system can alleviate pressure on the rest of your operation, allowing you to handle higher volumes without bottlenecks slowing you down.

Once the bottleneck is addressed, you can fine-tune downstream processes like packing, sorting, and shipping to support the increased throughput. By focusing on your most resource-intensive operations and continuously improving them, your distribution center will be well-equipped to meet the challenges of peak season while delivering consistent performance.

Incorporating the principles of TOC into your peak season strategy not only prepares your DC to handle increased volume, but it also lays the foundation for long-term operational efficiency and success.

Ready to optimize your distribution center for peak season?

Lift Automation specializes in streamlining DC operations through tailored automation solutions. Whether you need help with picking systems, material handling, or optimizing bottlenecks, our expert team can design a solution that fits your needs. Contact us today to boost your throughput and keep your operations running smoothly, no matter the season!